Category: Logistics

The drilling begins

Attaching the hose

Preparing the filters

Site update

Well, at long last, after all the preparation and hard work over many years, at 9:00am local time on Monday 10th Dec, right on schedule, we started up the hot water drill system. First was the boiler.

This was not as straightforward as we would have liked – the main burner unit blew a circuit board, the boiler kept over?pressurising when it fired and we then found that it was not burning as cleanly as we had been expecting. Eventually though, Andy and Andy pulled a rabbit out of the hat and got everything working.

Once the boiler was finally going, we needed water, and lots of it! Around 60,000 litres. This is equivalent to around 180,000 litres in volume of snow. So we started digging, and digging, and digging… for three days and three nights in shifts.

The first tank was filled and the heat?coil in the base of the tank slowly melted the snow. As soon as we had a full tank of water, the valve which connected to the second tank was opened and the water allowed to flow freely between them. We then carried on digging snow until both tanks were full. Finally, at around midnight on Wednesday, we were able to sit back and admire our work – 60,000 litres of water at approximately 5°C. Magnificent!

Now we had enough water to start circulating it through the filters and heat exchanger. We are using a four-stage filtration process to keep the drilling water clean. The filter resolutions are set at 20, 5, 1 and 0.1 microns. A 0.1 micron filter will be very effective at cleaning the water, however, just to be certain, the water is also passed through an Ultra Violet (UV) light chamber which is another common method for sterilising water. The end result is that the water used for the drilling process will be extremely clean, even before it is heated to over 90°C through a heat exchanger attached to the boiler.

So that’s about where we are at 1:30am on Thursday 13th December. The next stage will be to test the high pressure pumps and then to begin drilling down to form the cavity about 300m below the surface.

We are now committed, having gone past the point of no return. If anything stops working now, water could freeze in the pipes and the whole programme could come to a halt. So please keep us in your thoughts as we work round the clock for the next seven to ten days.

As always, many thanks to Pete Bucktrout, our cameraman, for all the outstanding images and video clips on this blog. Stunning!

Hot water at last!

Priming the boiler

Testing, testing…

Update from Chris Hill

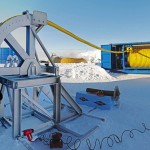

The ALE traverse team were on site for five days to help lift and place the heavy containers and move cargo and fuel around. They also made a massive improvement to the site by ‘grooming’ the snow to flatten and harden it using the two Prinoth BR350 vehicles. This gives us the advantage of building the drill site on a flat, level surface from the start and saves us from untold digging misery as we position all the equipment. The guys from ALE were brilliant and we would never be in the excellent position that we are now without their help.

We then had to connect up all the containers and generators – the entire site is powered by three?phase electricity. The hot water drilling system needs a lot of industrial plumbing work to move the water around and all of this needs carefully insulating and, in some areas, protecting with heat trace cable. There is a comprehensive data network across the site so that all the information from the drilling and instrumentation systems can be captured and monitored. And of course, everything needs fuel.

On Wednesday our skiway was used by a Basler DC3 and a DeHaviland Twin Otter, both from ALE base camp at Union Glacier. We were pleased to welcome Nick Lewis and Tim Hewitt and were able to give them a tour of the site and a hot lunch. It would have been extremely difficult for us to undertake this programme without the heavy lift IL76 aircraft capability and tractor traverse provided by ALE and so it was good for them to see the scale of the programme which they have been supporting logistically over the last two Antarctic seasons.

Finally, the day came for the science team to fly out to site. Their journey from Rothera Station began at 9:00am on Saturday 1st Dec and they flew by Twin Otter to Fossil Bluff, then to Sky-Blu then directly out to Lake Ellsworth. They arrived around 5:30pm in glorious sunshine and positively tropical temperatures of ?13C. This event triggered the departure of Iain, our BAS Field Guide. Iain has been invaluable, not only for his never-ending ability (and enthusiasm!) to dig snow, but also for his wealth of outdoor and Antarctic experience enabling us to progress faster and giving us the best possible start to the camp. He leaves with a massive thanks and appreciation from all of us at Lake Ellsworth.

It’s a funny feeling. We have been planning and designing and developing equipment for this programme for so long now (over three years) and the twelve people here have sat around a meeting table on many occasions during that period, but now, for the first time, we are together in Antarctica, at Lake Ellsworth, with all the equipment, as a team and we have to make it happen. No pressure then!

It’s great to have everyone here at last and the newcomers were put straight to work. Following an essential safety briefing, of course. This is an industrial scale engineering site in Antarctica after all! Martyn, David and Dom began work setting up the prep tent, the field laboratory where the initial samples will be processed and prepared for onward shipping.

While they were doing this, Martin worked on the installation of the main drilling and deployment wellhead, the point at which everything happens. Positioning the wellhead was a big milestone in the setup phase and it was a great sense of achievement to complete it.

Riet, our Camp Manager has been doing a fantastic job in looking after us all. Riet is a professional chef with many years Antarctic experience and he has taken care of most of the arrangements concerning the camp set up, food and waste management. We eat extremely well (Mexican chilli beef, tortilla wraps and guacamole this evening) and everything is home made. We even enjoy freshly baked bread every day. From all of us Riet, a huge thank you for everything you are doing for us – it is appreciated and makes a massive difference.

Once again, big thanks to Pete for some stunning photos and video. It is such a bonus having him on site to capture all this activity in a way that we never could.